I have now clocked almost 200 hours on the boat so far. The manual suggests it taking around 500 hours, so hopefully that means I am 40% there. However, given that I’m only on page 86 of the 284 page manual, there is a long way to go…

Fiberglassing is done one section at a time. Cut out a section of fiberglass, climb in and cut in to a T shape to fit the section, and try to neatly spread the epoxy evenly over the fiberglass. Fiberglass frayed ends, threads falling out everywhere… Finally done. Well, except for sanding it all.

Additional tape applied at the bow seams, as well as an extra strip all along the transom for good measure as I’ll definitely be having an outboard hanging off the end.

I plan to install a fish / depth finder, with an in-hull transducer imbedded within the hull between bulkhead 2 and 3. I added a couple extra layers of fiberglass and another section of plywood to stiffen up this section. I plan to drill a 3″ hole in the middle of the supported section, fiberglass the outside of the hull, and later place the transducer in the hole and fill with epoxy. Any other building thought of putting in a fish finder? I am thinking of placing the control unit near the port transom.

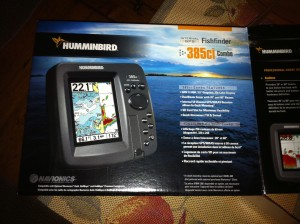

I selected the Hummingbird 385ci Fishfinder / GPS combo. Nice to have a fish finder, know the depth, speed and the GPS will be nice to have when the fog comes in thick. Selected a Fusion stereo receiver for its small size and having iPod, AM-FM and marine radio reception. The 6.5″ speakers combo set was $10 more, so now trying to figure out how best to mount the speakekrs. Any suggestions? Would like to use as small a box as possible, similar to the cardboard cutout pictured below. However, not sure if a bigger box is needed for the best sound.

Now starting on the cockpit supports.

Good progress so far, despite the distractions of the beach on the warm days.

Fancy shmancy-will she have Wii onboard?

Now that’s an idea…

Your method for mounting the transducer seems pretty clever. The one thing I’d watch out for is that when you fiberglass the hull, ‘glassing over the whole will be a challenge. The glass will want to droop down. And the epoxy will want to run right through the glass and drip all over your interior. Got a couple of ideas though. One is to keep the plywood from the center of the whole. Wrap it in plastic wrap, screw some sort of flange (like some 1×4 strips) into the back of it, put it back into the whole, and screw the flanges into the side of the boat with some short screws. This should give you a nice flush surface on the outside of your hull to apply the glass to. Once you’ve finished glassing, you should be able to easily unscrew it and remove the center of the whole again. Of course the risk is that it doesn’t come out so easily…

The other idea would be to permanently fill the hole with some material that is transparent to sonar, thus giving you a nice solid surface to glass over.

I’m envious of your progress!

Thanks for the ideas. I was thinking of something similar with some sort of plastic inside, but hadn’t totally worked it out yet. I like the suggestion of using the flange to fix it in place.